I finished the brace - well that part of the brace anyway

It weighs in about half of the original which was just horrible

I also carried on with the weight loss on the steering column by parting off the part of the boss that carried the Sierra steering lock mechanism - just nee a bit of thin plastic tube to slip over it to tidy it up

I also had a look at the rear suspension bushes - I had some from another project that were a hard Polybush but the crush tube was only 12mm and not 1/2" and the poly was 1/16" to big in diameter and the flange section was also a 1/16" to wide so I put them in the freezer and then modified them all in the lathe so now have some nice stiff poly rear suspension bushes.

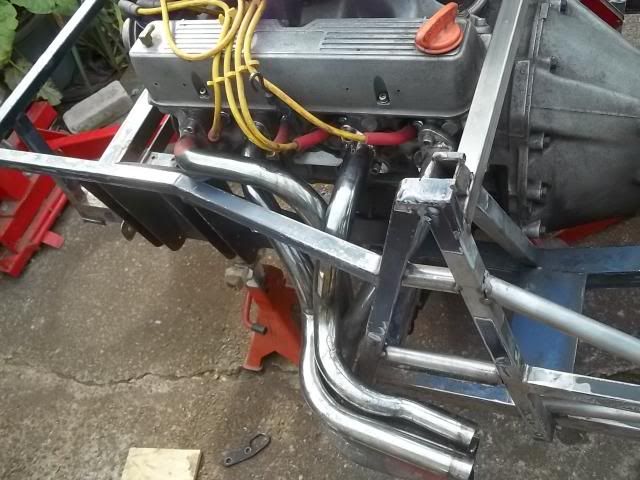

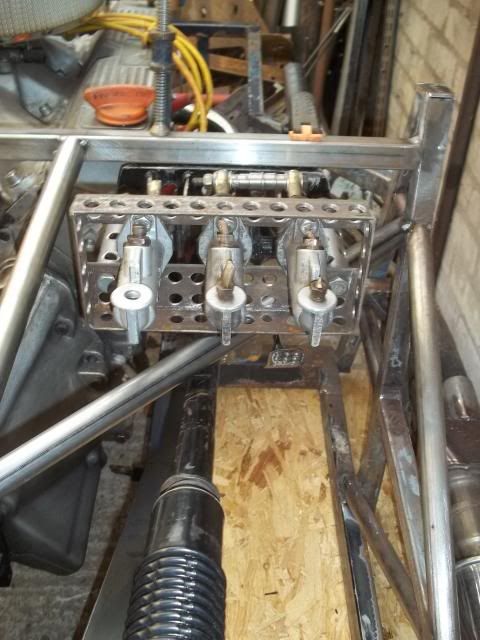

The pedal box on the car has been bothering me for sometime, it's in the wheel-arch surrounded by exhaust headers and exposed to whatever the tyre throws as it and very inaccessible for maintenance it has to be up two inches above the floor as the 2" chassis rail blocks the positioning of the M/C's.

The option is to make the pedals pendant type and have the M/C's inside the car behind the dash I can also lower the floor and have a sealed front bulkhead the same as the passenger side and maybe find a little extra width and length in the pedal box at the same time. I made something similar for an old Dutton I rebuilt and that worked quite well apart from being a bit of a challenge to get the reservoirs above the M/C's without coming through the bonnet.

More steel required - will needs some 30mm x 6mm strip now - back to the sketch pad to see if it will fit.

So whats been going on with the tunnel?

The weight loss is coming to an end and now its weight gain time

but before that a little more weight loss :laugh:

Going are those ugly side sills in heavy old glassfibre a test part was formed and fitted to see how it would go

I am liking that alot so I may drop down and see my local alloy supplier and folder to get a couple of panels made up for further trials

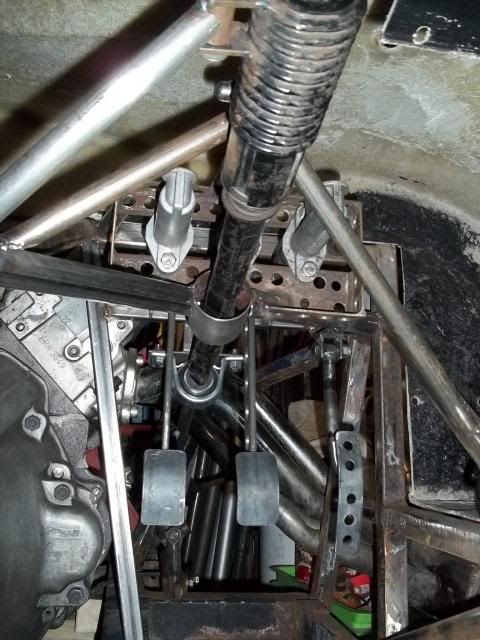

The central back bone tubing has started and I am quite happy with it now - it took a fair bit of thought to figure where and what shape I wanted it and it now flows quite well with the rest of the works so I am happy to carry on with it.

Throwing bits onto the chassis to get a visualisation

Putting a kink in to get a little more "me" room

This assistants got a bit bored by all of the tea drinking and sitting about looking.

Bits actually tacked up showing the shape of the tubing - Worth the extra effort involved with all the complicated profiling of the tubes to get a good join.

Only one pair of tubes are actually at 90 in two planes every other tube is not actually a parallel with any other which makes setting up cutting and welding a bit complicated

Its all progress.

[

[

[

[

[/URL]

[/URL]